Latest Products

1.Emulsion paints

2.Textured paints

3.Felxtured paints

4.Marble Trowel

5.Satin& Silk paints

6.Gloss paints

7.POP paints

8.Vinyl matt Emulsion

9.Fire Retardant paint

10.Anti Rust & primer coatings

11.Stucco paints

12.Pigment paste

13.Wall Filler

14.Screeding paints

15.Fluoresent paints

PAINT TECHNOLOGY

PAINT : Is defined as a dispersion mixture of one or more substances in a vehicle.

VEHICLE : Is a liquid consisting of non-volatile film forming material, a volatile solvent called THINER and sometime an oil.When paint is applied on a surface the thinner evaporated while the other components remain.

TYPES OF PAINTS

1. GLOSS OR OIL PAINT : These paints can only be thinned with organic or related Lacquer,Enamel,Industrial paints etc.They are based on natural or synthetic resins.

2. EMULSION PAINTS (WATER BASED PAINTS): Paints that can be thinned with water are usually called Emulsion paints.They are matt,hard,durable, protective and absorbs heat due to its porous nature.

3. Generally,paints could be domestic,industrial,primer,surface or finish.

IMPORTANCE OF PAINTS

(a) Beautification:Used to decorate

(b) Protective: Protects surface.

(c) Corrective: To cover or fill space

AREAS OF APPLICATION

(a) Domestic :House,Furniture,Kitchen wares etc.

(b) Industrial :Factories,Marine,Offices,Vehicles etc.

CONSTITUENTS OF PAINTS (RAW MATERIALS)

1. RESIN : This is the film forming part of paint.It also bind other components of paint to the surface.There are natural and synthetic resins.

Natural Resins | Synthetic Resin |

1.Limseed Oil | Epoxy Resin |

2.Castor Oil | Alkyd Resin |

3.Tung Oil | Acrylic Resin |

4.Rosine | Nitro Cellulose Resin |

5.Fish Oil | Polyvinyl Acetate Resin |

6.Soya Bean Oil | Polyurethane Resin |

7.Rubber Seed | PVC Resin |

Palm Kernel Oil etc. | Phenolic Resin etc. |

2. PIGMENTS/COLOURANTS :Pigment is a solid substance which give paint its desire colour.It also provides body to the paint.There are many types which are used solely or in combination with other pigments.These could be organic or in-organic.

PIGMENT | COLOUR | TYPES | 0PACITY |

Titanium Dioxide | White | Inorganic | Very High |

Zinc Oxide | “ | “ | Fairly High |

Lithophone | “ | “ | “ “ |

Aluminium Hydroxide | “ | “ | “ “ |

Ferric Oxide | Red | “ | Very High |

Red Lead | “ | “ | “ “ |

Chrome Red | “ | “ | “ “ |

Rubine Red | “ | Organic | “ “ |

Prussian Blue | Blue | Inorganic | “ “ |

Phthalocyanine Blue | “ | Organic | “ “ |

Chromium Oxide | Green | Inorganic | “ “ |

Halogen Green | “ | Organic | “ “ |

Molybdate Oxide | Organic | Inorganic | “ “ |

Brown Umbre | Brown | “ | “ “ |

Carbon Black | Black | “ | “ “ |

Chrome Yellow | Yellow | Inorganic | “ “ |

Zinc Chromate | “ | “ | “ “ |

Litharge | “ | “ | HIGH |

3. EXTENDERS/FILLERS :These are cheap,low refractive materials added to paints to reduce cost, increase durability and give body to the paints.Examples of important extenders are talc, Barytes,Silica,Mica,Gypsum, Clay, Kaolin, Caicite, Calcium Carbonate, Magnesium Silicate etc.

4. DRIERS : Driers are catalyst which carry oxygen (air) into the paint system. They accelerate the drying of the paint through oxidation,polymerization and condensation.Important driers are resinate, oleanatenaphthenates of Cobalt,Zinc, Calcium, Serelium,Lead, Manganese etc. Cobalt driers are the most efficient and are surface driers. Lead are bottom driers, Manganese,Zinc and some others are thoroughas surfactants and emulisfiers.Polyvinyl acetate based paints do not need driers as they are fast drying.

5. EMULSIFIERS : There are soaps that help in dispersion/wetting of the soild components of the paint.They by their nature blend with both oil and non- oil (e.g water) materials zinc drier, sodium lecithin, soya lecithin,sodium lauryl sulphate,cetrimideetc.are good examples.

6. THICKNER : Carboxylmethyl cellulose (CMC),Hyroxylmethyl cellulose such as Natrosol,Cellasize,Bermosol,Carbopol are common types. There are the organic ones. Inorganic ones include bentone,Easy Gel, Econogel etc.

7. PLASTICIZERS : They provide elasticity,minimize cracking of the paint,make the paint to flow.Tricresylphosphate,Dioctylphthalate, Dibutyltartarate are common example.They are very necessary in wood,Leather, metal and plastic paints.

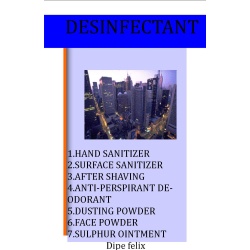

8. BIOCIDES : Chemicals that kill micro- organisms such as algae, fungi,mucour, etc are added into paints to prent it from decay.Emulsion paints usually contain these items Formalin,Cuppersulpate,Acticide, Pine Oil, Methyl paraben, Propyl paraben Acticide, Chloroxylenol,Cetrimide are used.There items are hardly incoroporated into oil paints due to the fact that resins are rarely attacked by microbes.

9. ANTIFOAMS: Pine Oil, Silicon Oil,Whitespirit,Kerosene, Gasoline are materials that can stop excessive foaming in paints systems.

10. FLOATING AGENTS : CMC, Bentonite,Procol,Calceletc are some times added to paints to reduce the tendency for the solid water in paints to settle at the bottom.

11. ANTI SKINNING AGENTS : Oil paints have the tendency to gell or skin.To avoid this wastage of paint polyhydraoxylphenols,oximes, Polyalkyl amines are incorporated in to the paints.

12. OTHERS :Whitening agents such as tinapol,Aluminium Silicate are put,waxes such as Bee wax,carnubau wax, PJ, montan wax can also help the paint to set crack free.BUFFERS AND PRESERVATIVES such as sodium benzoate, sodium citrate, citric acid are sometimes employed to reduce undesired reactions in the paint, Starch, Protein Casein are used as Stabilizers.

13. THINNERS & DILUENTS: These are very important solvents which reduce the viscosity of the paint; desolve the resins and solids suspend solids, help in drying among others.They include: water,kerosene,Alcohol,Ketones,Acettates,Petroleum solvents Glycols etc.

Up to 80% of these raw material imputs in paint can be sourced locally. A 100% local raw material based paint is being tested.

QUALITIES OF A GOOD PAINT

1. It must be fluid enough to enable easy application.

2. It should posses high covering power

3. It should form tough, uniform, adherent,impervious film.

4. The film should not get cracked on drying.

5. It should protect/decorate the painted surface.

6. It should form a lustre or clean film.

7. The paint should be stable and durable.

8. It should not be poisonous to the user (for domestic paints mosly).

9. It should have a good pot and shelf life.

10. The paint should be the type that can be applied by one or more of the following methods:

(a) Brushing (b) Rolling (c) Spraying (d) Dipping (e) Tumbling depending o n the surface to be painted.

Any paint that does not meet the above standards is likely to fail by way of CHALKING,FLAKING,CRACKING,CHANGE OF COLOUR OR UNAPPLICATION.

PAINTS RAW MATERIALS

1. Resins (Synthetic) (2) Resin (Natural)

a. Alkyd Resins a.Linseed Oil

b. Acrylic Resins b.Soya Bean Oil

c. Nitrocellulose Resin (NCR) c. Coconut Oil

d. Polyester Resins d. Castor Oil

e. Polystyrene Resins e.Rosin

f. Epoxy Resins, Phenolic etc. f. Tall Oil

g. P.V.A. (h) P.V.C. g.Fish Oil etc

h.Bitumen

3.PIGMENTS

Titanium Dioxide –White (4) Additivies (Natural)

Zinc Oxide “ (A)Driers: C0,Zn,Pb,Mn,Ca,Al,

Aluminium Hydroxide “ S e Salts.

White Lead “

Lithophone “ (B) Antiskinning Agents

Carbon Black “ (1) Mekoximes

Bitumen “ (2) Polyhydroxyphenols

Prucian Blue

Halogens Various colours (3) Polyhydroxyamines

Red Oxide Dark Red (4) Engenol

Yellow Oxide Dark Yellow

Lemon Chrome Bright Yellow (c) Plasticizers

Middle Chrome “ ”

Chromium Oxide Green (1) Dioctylphosphate DOP

Burnt Siena Brown (2) Tricresyphosphate TCP

Van dyke “ (3) Tributylphthalate

Litharge “ (4) Dibutyltartarate etc.

Rubine Bright Red

Molybdate Salt Orange (D) Extenders or Fillers

Venetian Red

Lead Chromate Red to Orange (1) Gypsum

Yellow (2) Talc

(3) Mica

5.Solvents & Diluents(Thinners) (4) Limestone

A.Aliphatics (5) Barytes

White Spirit (6) Chinaclay

Kerosene (7) kaolin

Petrol (8) Diatomite

Gasoline (9)Silica etc .

Hexane etc.

(E) Antifoams

B. Aromatics (1) Silicon Oil

Toluene (2) Pine Oil

Xylene (3) Glycols

Naphthalene

Turpentine (F) Dispersants

Aromasol (1) Soya Licithin

(2) Soaps (Natural)

C. Alcohols (3) Detergents (Natural)

(4)PA1000

Ethanol (5) Clycol Ester etc.

Isoprophylalcohol, IPa

Isobutylalcohol SBA (G) Thickners

Butanol (1) Hydroxycellulose

Propanol (2) Hexanol

Methanol (3) Bentonited

(4) Polygeletc .

5.D. Esters (4.H.) Biocides

Ethyl Acetate (1) Pine Oil

Butyl Acetate (2) Acticide

Propyl Acetate (3) Formalin

Isobutyl Acetate (4) Copper Sulphate

E. Ketsones (I) Preservatives

Acetone (1) Sodium Benzoate

Methylethyketone MEK (2) Methyl Paraben

Methylisobutylketone, MIBK (3) Propyl Paraben

(4) Ammonia etc.

F. Glycols (J) Waxes

Oxitol (1) Beewax,Linolin,

Carnubawax

polyethene wax.

Ethylglycol

Butylglycol

Butyloxitol

Ethlglycol acetate.

6. Chlorinated Hydrocarbons

Carbontetrachloride (Chloroform)

Trichloroethane etc.

PAINT PRODUCTION MACHINE

Paint being of thin vehicle system compared to paste may be prepared in

(a) Tripple roll mill with contact rollers.

(b) Ball mills (Bead,pebble mill)

(c) Shot mill

(d) Sand mill

(e) Speed mixers etc.

However, where solvent or volatile materials are negligible or absent shot mills and other open-style intensive mixing systems may be used together with speed mixers.

The choice of equipment for paint production or manufacture ultimately depends on;

(a) The volume to be produced

(b) The pigment hardness

(c) Presence or lack of volatile solvents etc

(d) The body or viscosity of the finished product.

(e) The method of application of the paint could also be considered.

The manchine are locally available now: information on machines are available on request.

SOME INK/PAINT LABORATORY TEST EQUIPMENT/TOOLS

S/NO | EQUIPMENT/TOOL | APPLICATION | REMARK |

1. | Grind Gauge | For checking degree of dispersion(grinding) | Simple to handle |

2. | Draw-down kit | For checking colour match | “ |

3. | Palatte& knives | For mixing & handling paints | “ |

4. | Weighing scale | For weighing materials | ” |

5. | A colour chart | For Refering to standard colours | “ |

6. | A slab | For working on colours | “ |

7. | A stop watch | For timing | “ |

8. | A viscosity cup | For testing viscosity | “ |

9. | Glass wares | For General laboratory work | “ |

10. | A density Bottle or equipment | For checking density | Needs expertise |

11. | A Band Tester | For Hardness Elasticity | “ |

PAINT PRODUCTION

The “Chemist” must consider all available option in terms of the factors below when formulating paints.Viz:

(a) Cost of production

(b) Ease of production

(c) End users requirement

(d) Raw materials available

When a specific formula has been developed the stages of production is then followed to enable him arrive at a good product.

Before the full scale batch is made it is very necessary that the following pre-production basic are done.

1. COLOUR MATCHING: At the “test tube” level the appropriate colour required is developed and checked before the batch is made by scaling up the values obtained during colour matching.

2. PIGMENT/SOLID COMPONENTS HARDNESS: If the hardness of the pigments/solids to be used are know, a lot of time,energy and labour will be saved by using appropriate methods.

3. WEIGHING: Accuracy in weights taken saves money and gives good products. The weight master must be well trained and should be a careful hand.It is necessary to check the weighing scale each time a new weight is to be taken.Errors in weight in paint making bring about off- shade and its attendant wastage and higher costs.

- Availability: In Stock